This is about different projects that I do from wood; carving, turning and construction. Enjoy.

Friday, December 23, 2011

Corian Spiral

Saturday, December 3, 2011

Santas and More

Tuesday, November 22, 2011

Not yet forgotten

While I haven't posted any pictures on this site, I have been busy. I'm taking a metal smithing class to learn more about making hinges for my boxes. Naturally the first real project in the class is a ring. It is not ready for pictures yet, but I have been learning how to solder as well as shape metal. I've worked with brass, copper and silver. Each one has their own unique qualities and it is all fun.

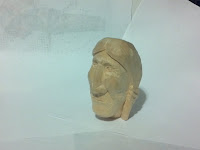

Also, I've finally started painting all of my carvings - Santa's, houses, ghosts and Indians. These are also not ready for pictures. There are other projects in the works, but none of the very far along. I have prepared some maple for a scroll sawing set of collasapable bowls. I'm part way done with a set of hinges. I turned a large button to be used as wall decor. That and trying not to keep too busy.

Well enjoy, and be careful of the splinters.

Wednesday, October 5, 2011

Myrtle Wood Bowl

Since it is tough to edit, I'm not making any changes. In addition, I added a couple of pictures of a bottle stopper that I am carving.

Sunday, September 11, 2011

Decorative Horses

Enjoy and be careful of the splinters.

Monday, September 5, 2011

Some Carving

Tuesday, August 16, 2011

The Shell Game

Earlier this summer, I was at the beach near Gray's Harbor, Washington. One of the small shops there had sea shells for sale at what I thought was a reasonable price. I picked up a couple as an experiment and you'll see one of them here. The glue is still drying on the other. The spindles are turned from walnut and have a stub tenon that matches the holes (kinda) found in the top and bottom of the shell. I attached them with E6000 craft glue as that is a thick glue, dries clear, and has some flexibility. These two shells cost $1.69 each, making this a fun little inexpensive project. They are fragile so I didn't know if I could get them home in one piece, but they made it. The finish on the wood is super glue, as I was trying to keep the pieces as strong as I could.

Enjoy, but be careful of the splinters.

Thursday, August 11, 2011

A Little Magic

A good friend of my sons has 2 daughters that went to Hogwarts Day Camp last week. Each was given a branch to polish and make into a wand. One was lost on the last day of camp, to the disappointment of the girl. Well, since they had asked already if I could help get the wands polished (sanded), I went ahead and made a couple of wands which you see above. Each wand is about 16 inches long, with the business end made from Myrtle wood. The Handle of one is Cherry and the other is Juniper. Since I made these from 2 pieces, I drilled the tenon hole extra long and added a partial feather voluntarily donated by a Blue Bird. Okay, its a feather I found on the ground, and maybe the cats didn't get him.

Enjoy, and be careful of the splinters.

Sunday, July 31, 2011

Sewing Room by IKEA

Some assembly required.

This was my weekend. After spending weeks of unable to decide or describe what was wanted/desired in the sewing room (except not wanting tacky, whatever that means) we went to IKEA and purchased a complete desk set for the sewing room. The white is a melamine covered particle board with precise hole and fittings locations to match perfectly with a metal tube support structure to complete this desk. Everything is included, even the required allen wrenches in multiple separate packages neatly waiting in the warehouse for pick-up. The engineering is very good, the price is low, though I would prefer a better quality material, the price would go up then to match.

I built the table the first night. I had to built it right-side up, not according to the plan, as I had no way to turn the table right side up after assembly. But it went together well and all of the parts fitted to a tea. In fact it looked so nice the next day we went out and bought 3 tall bookcases and 2 short bookcases. One each of those stayed in a different room. These were heavier, which did create a problem for me, but I was able to move them around. The side and end panels of the bookcases are not solid, they just look that way. More like a large torsion box with solid members in just the right places for strength and to assemble the parts.

Note that the bookcases are all off the ground and are hanging with molly bolts near the top. The larger shelves are actually sitting on a frame where the cement juts into the room around the inside perimeter of the house. One day of assembly for the bookcases, one for the table. I've made nothing this week/weekend.

Enjoy, and be careful of the splinters.

Tuesday, July 5, 2011

Another for the Birds

This was a rough bit of turning to reduce the wind vanes to the main body of the roof. Once knocking off the extra wood, it became much easier turning, and a lot fewer flying chunks of wood.

To turn the bottom, I first turned a cavity into my mounting block where I could insert the top, added hot glue, and turn the hollow in the bird house top.

A this point I was able to complete the turning, carefully making sure that the bottom part of the bird house fit snug in the opening in the top. After a creating a place for the top to fit, I hollowed out the top, put finish on the two parts and glued them together.

Enjoy and be careful of the splinters.

Monday, June 27, 2011

Another Birdhouse

This is a collection of pictures I took while turning the second birdhouse. The pictures show it all. Note that I took these with my Acer tablet and wrote this while I was waiting for the drill to cool off.

With any luck the pictures stayed in the order I took them. The software I used is called Blogger and was written for the Android tablet. No preview to see how it would look, also no editing of the pictures and all of the writing is with my thumbs.

I had to move into the house to get close enough to the wifi to post this article.

Enjoy, and be careful of the splinters.

Note that the pictures did not come in the requested order, I went in and re-arranged them.

Wednesday, June 22, 2011

Turned Bird House

Here is a quick project that was fun. Again, as with the pens below, this is a project to raise money for our Holiday Party in December. The body of the bird house is Myrtle Wood and the roof is spalted maple (I think). The perch is walnut and the red bird I carved from basswood and colored with water colors. Yes, the house is hollow out and the walls are about 1/8" thick. No reason to get too crazy here. The bird is attached with super-glue. The finish is a walnut oil & shellac mix.

Enjoy, and be careful of the splinters.

Wednesday, June 15, 2011

Getting Ready for Our Summer Auction

Every year at work we raise money for our Holiday Party with an auction of donated items. Here are two corian pens and a Cedar Bottle Stopper I turned. The first pen was from a piece of corian that I thought was to bland to be very viable. As a pen, it looks pretty good. As a counter, just not enough color for me. The second pen is from a small piece of blue corian that I thought was pretty good looking, and it is. I think I would like to try the blue again using a black tip and center band. That means I would have to turn those too, which doubles the time and work. The fit and finish on these pens are good, so with a replacement ink cartridge I would sell either for $45.

The last item on today's posting is a simple bottle stopper I made from ceder and put a walnut oil/shellac finish on it. Cedar turns quick and sanding is more of a concern due to the softness of the wood. The two colors are because the piece is off the edge of the log, giving it a lot more character.

Enjoy, and be careful of the splinters.

Tuesday, June 7, 2011

Pen Box

Well, I did decide to try and make a small box for the pen. The first picture shows the box, cut with 10 degree angles. I cut the channel of both the top and bottom as one piece using the table saw, many passes across the saw, then hand sanded to remove the resulting grooves. It's about 7 inches long. The main body is Myrtle Wood and the ends I think are from Yew. Whenever I cut or sand it it smells bad, more like 'ewww'. Still, it looks nice though yet unfinished. I hand-made a single hinge for the box also from Yew thinking that it would be strong enough for these pieces. The hinge pin did not drill exactly centered. When I opened the box you can see how the lid cants to one side. Not good.

Well, I did decide to try and make a small box for the pen. The first picture shows the box, cut with 10 degree angles. I cut the channel of both the top and bottom as one piece using the table saw, many passes across the saw, then hand sanded to remove the resulting grooves. It's about 7 inches long. The main body is Myrtle Wood and the ends I think are from Yew. Whenever I cut or sand it it smells bad, more like 'ewww'. Still, it looks nice though yet unfinished. I hand-made a single hinge for the box also from Yew thinking that it would be strong enough for these pieces. The hinge pin did not drill exactly centered. When I opened the box you can see how the lid cants to one side. Not good. I removed the hinge from the box, (no it wasn't easy) and put supports to lock the lid in place on both ends. These I cut on the scroll saw and sanded them to fit. I made a handle from Yew for the top and it has become a lift-box. I sanded a little from the ends of the lid to allow the lid to slide on a little better. On shot shows the pen set into foam that I had available. The finish is BLO and a layer of Watco wax. It looks nice.

I removed the hinge from the box, (no it wasn't easy) and put supports to lock the lid in place on both ends. These I cut on the scroll saw and sanded them to fit. I made a handle from Yew for the top and it has become a lift-box. I sanded a little from the ends of the lid to allow the lid to slide on a little better. On shot shows the pen set into foam that I had available. The finish is BLO and a layer of Watco wax. It looks nice.

Enjoy, but be careful of the splinters.

Wednesday, June 1, 2011

A Duck Pen

Still need to decide if I should make a box for it, or pick one up at either Woodcraft or the Rockler store.

I found a mouse to use as a prop for the pen, no significance, just handy.

Enjoy, but be careful of the splinters.

Monday, May 2, 2011

New paint

My spouse was out of town, so I cleaned out the second sewing room, painted it twice, then installed a Dupont floor (like Per go, only different).

Note that I was a box of flooring short, and I've been laying this floor for about 6 years, it was no longer in stock. I bought the closest color match I could, and decided not to worry about it.

Note I posted this from my android tablet.

Tuesday, April 19, 2011

From Corian

I tried to show how I press the pen pieces together, but the picture is fuzzy. The point was that I turned two blocks for the lathe that allow me to use the lathe itself as the press. Makes it easier than buying another tool. These wear our so I get to keep turning these blocks and tossing the old ones. I considered using corian for the blocks, but I thought it might be too hard.

And of course, the final shot. This pen is laying on the back side of the piece of corian I turned.

A final shot is a green and yellow pen. The center band is black acrylic that is part of the pen. I also turned a black tip for the pen, which you will see when the pen is finished. I haven't decided about whether to put a clip on the pen, or just top it with a black turning. Come back later and see.

Enjoy and be careful of the splinters.